The manufacturing sector is known to be included as one of the major parts of the economy, this is because it accounts for 16% of the Global GDP as of 2018. Because of this many governments or countries across the world keep focusing on how to encourage the manufacturing sector. Certain activities in rising economies to advance the manufacturing sector includes Make for India and Made in China (MIC) 2025. Made in China 2025 is known to be the first stage of a large three-step strategy that has been put in place to transform China into a leading manufacturing power. This initiative tries to move China up the global manufacturing value chain by using manufacturing technologies.

What’s more, “Make in India” is an activity that was propelled in 2015 to energize the production of goods in India. This was done to reduce India’s reliance on the export of goods by producing goods in their own country. Since its launch, the FDI in the country has seen an optimal trend. FDI inflow in the country was $286 billion, and this was recorded from April 2014 to March 2019. This figure recorded is nearly 46.9% of the Overall received by the country since April 2000. However, since the outbreak of COVID-19, global FDI inflows has seen a sharp decline.

We are living in a new trading environment due to implications created by COVID-19, and this has left many manufacturing industries with a few rising risks. Some of the impacts of the outbreak of this disease on supply chains will affect the manufacturing industries in many ways. These impacts on the manufacturing industries have not been anticipated and this could leave several businesses with more risks than anticipated (according to a survey conducted by the National Association of Manufacturers, about 80% of manufacturers are expected to have financial difficulties in their business).

According to estimations made by the United Nations Conference on Trade and Development (UNCTAD), the outbreak of COVID-19 can cause a global FDI to shrivel by 5% to 15%, this is because of the downfall in the manufacturing industry which is coupled with factory shutdown.

The negative impacts of COVID-19 on the FDI are relied upon to be high with regards to the energy, automotive, and airline industries. In the electronics sector, consumer electronics and smartphone companies are beginning to reduce production operations and postponed the introduction of new products because of the outbreak of COVID-19, and this has interrupted the supply of components.

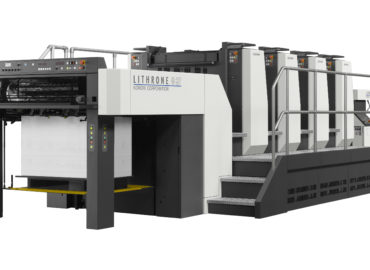

The assessment of the impacts of the virus on the manufacturing industry all around the globe is arranged into various sections such as automobile, chemical, electrical and electronics, and others. The electronics industry is in effect altogether influenced because of the COVID-19 pestilence, as China represents almost 85% of the total value of components used in cell phones and about 75% on account of TVs. Every single basic component, for example, printed circuit boards, LED chips, memory, mobile displays, open cell TV panels, and capacitors are imported from China.

The majority of these Chinese factories were closed down due to the coronavirus pandemic. Subsequently, in January 2020, Chinese merchants have increased component prices by almost 2-3% attributable to a shortage of supplies because of the factory shutdown. Consequently, it has negatively affected the manufacturing sector around the globe.

Furthermore, the impact of COVID-19 on the manufacturing industries has been analyzed based on regions that include Europe, North America, Asia-Pacific, and the Rest of the World. When the Asia-Pacific is picked, China is the country most affected by this pandemic, because of the fall in industrial production which has followed with the shutdown of factories.

In Europe, there has been a temporary shutdown of most of the automobile companies and electronic manufacturers, or a minimize in the production output, which has resulted in a loss to the global trade. For example, Volkswagen the automobile company publicly declared a temporary shutdown in the production of vehicles and engines at its various factories in and around Europe because of the outbreak of the virus. This initiative taken by the company is focused on the well-being of their workers.

Some of the companies that are gradually getting affected by the coronavirus outbreak include Ford Motors Co., Samsung Electronics Co., BASF SE, and Boeing Co. A few of these companies are trying to cope with the impacts of the outbreak by shifting their production facilities to other countries which have been affected less by the COVID-19 pandemic. An example is Samsung Electronics Co. Ltd. In March 2020, Samsung declared that it will be shifting some portions of its domestic production of smartphones to Vietnam, this is because of the fast growth of COVID-19 cases in South Korea. This move was done to minimize the potential effect of the virus on its manufacturing operations.

THE WAY FORWARD FOR MANUFACTURING COMPANIES

As the COVID-19 pandemic continues to unfold, engineering and manufacturing companies are being hit on numerous fronts. However, how the company will be impacted depends on the portions or segments served and where the company sits in the industry’s value chain. For example, large manufacturing companies having access to federal contracts will likely have some protection, and this form of protection can be extended to a lesser degree to companies that hold state and local contracts. Projects that have been commissioned by private enterprise, may not be secure, especially if the contract at hand is with companies who have been affected largely by the outbreak of the virus because of the volatility of the markets.

How fares of the subcontractor middle-market amid this crisis in the short run could dictate how the industry will generally fare in the long run. Keeping workers in the manufacturing industry safe and subcontractor firms’ balance sheet healthy is critical to the general recuperation of the industry. This will likewise help to forestall a potential buying spree of distressed middle-market firms by foreign investors.

Large manufactures also need to look past their financial feasibility. They need to cooperate with the public sector to help come up with plans that focus on public safety and the dissolvability of their workforce, while they continue with their operations. This approach should be made relevant for firms planning, designing, and building projects that are related to critical infrastructure, for example, energy and power, communications, food, and agriculture, transport, and others.

Many manufacturing and construction companies will be constrained to make cuts during this unstable period, and some will be severe. So being careful with cuts while balancing short and long-term needs is important. Although doing this quickly can create an advantage, knowing where you are heading helps to ensure that the changes made are impactful.