Reverse Engineering Technology is the study of the design and operation of a product. This is the process of carefully acquiring the details, specifications, and formation of a product. To achieve this, you have to dismantle the machine for proper evaluation, analysis, and examination of the various parts.

Contrary to the perception of many, reverse engineering does not apply only on a product as a way of creating a duplicate or as a process of altering the original product. It is, however, applies to products to ascertain the manufacturing processes in their creation. It is also a useful way of creating new features for newer models of the same product. Competitors also use reverse engineering as a way of deciphering the advantage of the rival company, and to create products with superior features.

Branches of Reverse Engineering Technology

Reverse Engineering is relevant to various fields of science, such as chemical, mechanical, electronic, and software engineering. There are also different types of reverse engineering:

- Reverse Engineering of Protocols: This is the branch of reverse engineering useful in decoding the laws that guide message templates and the process by which they are communicated.

- Product Reverse Engineering: It breaks a product into its different components with the intent of identifying how they function and the relationship between them.

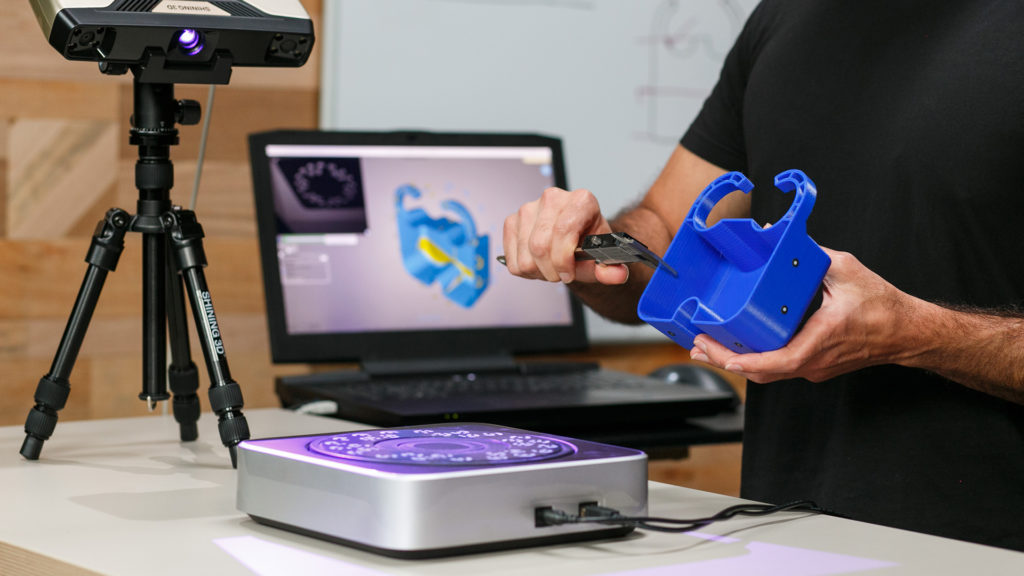

- Reverse Engineering of Machines: Reverse engineering examines the structure and functions of products to create 3D models. For legacy products and systems, it creates advanced duplicates in the future.

- Reverse Engineering of Military Applications: Countries utilize this during wars to imitate the intelligence behind the technology and weapons used by other nations.

- Reverse Engineering of Software: Reverse engineering inspects and analyzes the different components in a system, to develop complex versions.

Useful Tools in Reverse Engineering Technology

There are different software used for Reverse Engineering, they include:

- 1DA-Pro, Hex-Rays: This is one of the most popular tools useful for software reverse engineering. It identifies the functions, representations, and structures of data. It is also able to create graphs and build diagrams.

Its major plugins are:

- LightHouse: This software identifies and provides information on the sections of the codes that are involved in the execution, so you know which code to give attention to.

- ClassInformer: This software checks for data on RTTI which houses the file that is to be executed.

Other major tools used in software Reverse engineering include:

- WinHex: This Hex software makes available unique features and tools, as well as shows codes of files.

- PEiD: This is a reverse engineering tool that identifies the packer and confirms that the packing status of the application.

- Ghidra: This software enables disassembling and decompilation. It is compatible with Mac, Windows, and Linux.

- Radare 2: This is an application whose features include a disassembler and remote debuggers.

- API Monitor: This software that disrupts API calls and gives reports of data (input and output).

Importance of Reverse Engineering

Why is reverse engineering relevant to several branches of engineering and various industries?

The importance of Reverse engineering to the advancement of science and technology is immense.

They include:

- Reverse Engineering is useful in determining the method by which two or more systems function, and the relationship between both.

- Reverse Engineering is vital to the military to determine the strength of the foe’s arsenal and to build more robust weapons. It is very essential for victories in war.

- To create components of newer models of products that are becoming obsolete, production companies need Reverse Engineering.

- Reverse Engineering is also required to ascertain the authenticity of the competitive advantage of rival brands.

- It is beneficial in cutting unnecessary costs, very vital for the replacement of faulty devices. You get to replace just the component that is malfunctioning rather than the whole item.

- Reverse Engineering enables you to access information on the components of a product, enabling you to create or build better versions. In other words, it leads to newer innovations.

- Through Reverse Engineering, you can identify and detect errors during the production stage and also correct it before releasing the products to the public.

- Reverse Engineering also enables efficiency and the maximization of resources, thereby reducing production costs.

Role of Reverse Engineering in Manufacturing Industry

Reverse engineering is very relevant to the manufacturing industry. The creation of the CAD model of a product when the original one cannot be accessed is made possible by Reverse Engineering. Through this process, the digitization of the physical components of a product becomes feasible. Reverse Engineering is also necessary to produce better designs and models of the same product.

Through Reverse engineering, the operation, components, and functionality of a very old product when the authentic technical drawings are lost, or the manufacturers have stopped production. Making of duplicate becomes possible through this process. Similarly, examining competing products to confirm the quality of the components.

Reverse Engineering is also helping to reduce the costs of the purchase of the faulty product. Rather, the parts responsible would change at a lower cost. Reverse Engineering is also very relevant to the enhancement and efficiency of production processes, as well as to increase the quality of products.

Future of Reverse Engineering

There is no limitation to the possibilities of Reverse Engineering. The creation of more dynamic program languages is useful for better analysis. Reverse Engineering would make progress with the examination of data. Through this process, greater prospects exist in the manufacture of products, as duplicating of any device or system can be easy.

It is believed that by 2030, even duplicating of major organs of the human body would be done through Reverse Engineering. The brain tops the list of these organs, and there is the desire to create a superior intelligence that functions better than the human brain. Reverse Engineering would also facilitate the production of robots to completely replace humans in the manufacturing industry leading to increased productivity, less time usage, enhanced accuracy, and longer hours of work. You can discover more about 3D Screen printing right here.

Do you have any questions on Reverse Engineering Technology like…?

- How to start a Reverse Engineering project?

- Popular Reverse Engineering companies in the world?

- How much it cost to do a Reverse Engineering project?

- Where to find Reverse Engineers and companies?

Or maybe anything else on your mind that relates Reverse Engineering, kindly follow us and drop your comments below. We will get back to you promptly.